Benefits

- Using in-situ derived materials on the Moon reduces the dependency on Earth-sourced building material

- Improved processes for extraction of mineral resources from the lunar surface

- Robotics automation for remote operations

- Establishes space civil engineering processes for lunar construction.

Technology

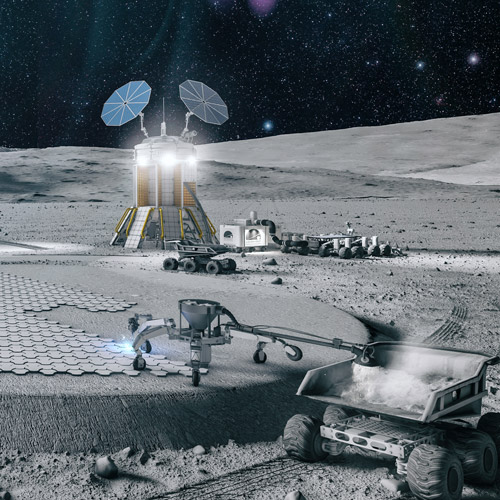

Astroport’s technology addresses two challenges of in-space construction: (a) converting indigenous source material (regolith) into durable construction feedstock and (b) robotic emplacement and assembly of the same into surface structures such as landing pads, roads, and habitats.

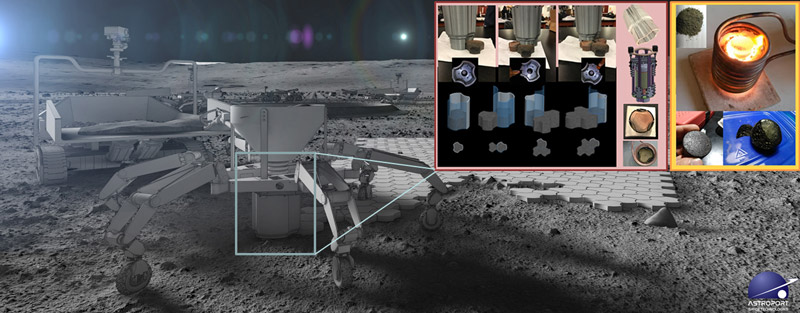

Astroport’s Lunar Regolith Melting and Lunar Regolith Binding stabilization and solidification technologies are used for manufacturing feedstock for lunar construction, as well as advanced engineering applications, such as in-space component fabrication. Their robotic construction platform is a unique furnace-printer for single step regolith melting, forming, and precise autonomous placement of in-situ 3D printed bricks. Other development products derived from the lunar furnace process include basalt fiber pulling for geotextiles, rods and tubes, and extraction of volatiles/minerals for metals and gases. Astroport’s regolith binding process produces filament and pellets for 3D extrusion printers for habitat construction or for detailed additive manufacturing.

Potential markets

Space is a nascent and rapidly developing economy projected to exceed $1 trillion in the next 20 years. Astroport’s primary target segment is critical infrastructure for planetary surfaces, with a focus on technology and equipment development, construction, and, eventually, operations of landing/space ports for camp resupply missions. Size of this market and volume of operations will be determined by the commercial demand for space transportation from mining, tourism, manufacturing, and other industries. Additional addressable market includes regolith processing and regolith-based materials manufacturing for in-space components fabrication, in-situ extraction of metal minerals or volatiles (oxygen).

Astroport’s technology has the potential to be utilized for low cost and rapid construction on earth (by licensing IP and operational know-how; material processing; assembly automation; remote operations). In-situ resource utilization of locally sourced material could have potential terrestrial applications, for low cost housing for low income indigenous housing and/or next-gen, ecological advanced construction applications.

IP status

The team has a US patent pending for an actuating printer nozzle and expect additional patent filings for their regolith melting furnace.

Partnering opportunities

Astroport is seeking Australian venture partners with expertise in mining and excavation automation technologies, and minerals processing.